A few days ago it has been demonstrated using graphene battery characteristics of fast charge technology in Japan, and said that this technology will be applied to new handsets. During the China International graphene Innovation Conference in October this year, Huawei a report entitled "Part of Huawei Products Requirements for Graphene research" report. Huawei will analyze which direction graphene for the product. It seems to follow after much practice with the signing of Manchester, Huawei so quickly action it!

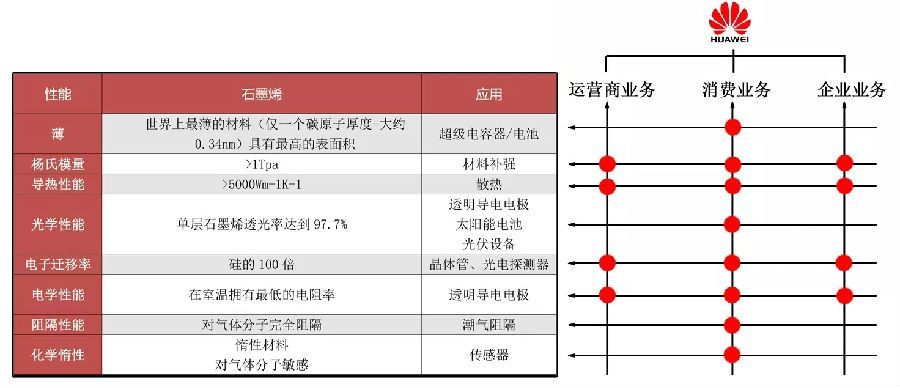

Graphene material has many unique properties, Huawei started from 2015 graphene research, its products and application of graphene materials have some intersection.

(Please see the chart below)

Stronger demand for products containing three more resilient and more resistant to environmental corrosion of electronic products more flexible, thin change

1. Metal Composites

Demand characteristics of the composite metal material: Young's modulus / Tensile strength / high thermal conductivity

Aluminum is widely used in Huawei's base stations, mobile phones and other products. We hope that the future can enhance the properties of graphene aluminum, in order to achieve the following targets:

1) high tensile strength and rigidity: Tensile strength> 700Mpa, yield strength> 600Mpa, the modulus of elasticity> 1000 GPa, elongation of> 10%, the thermal conductivity of> 140w / m.k.

2) thermal conductivity: thermal conductivity> 350 w / m.k, yield strength> 400Mpa, elongation> 10% of the price of the new material can not be increased, or the increase is too high. By this means the material can easily be surface treated by means of anodic oxidation.

2.Corrosion demand characteristics: Anti-permeability / electrical properties

In this aspect, graphene has two different applications, graphene nano-coating is one solution.

1) copper bus bar in the communications equipment industry has often been used. Tinned copper bus bar layer is very susceptible to oxidation. Therefore, the need to develop better anti-corrosion copper bus technology.

2) outdoor products, anti-corrosion coating (metal cargo containers, magnesium alloy, aluminum die-casting), under extremely harsh conditions can be used for 10 years. Challenge 1000 hours of neutral salt spray test (NSS test) without any corrosion. Finishing coating thickness is less than 100 microns. Sulfate sputtering test by IEC60950-22.

Prices of new materials to improve or not improve much.

3. Flexible and slim demand characteristics: flexibility / high conductivity / high thermal conductivity

We are very concerned in the field of heat graphene applications including flexible displays, batteries, monitors, heat transfer film and so on.